- +977-9817826183

- info@janakicable.com

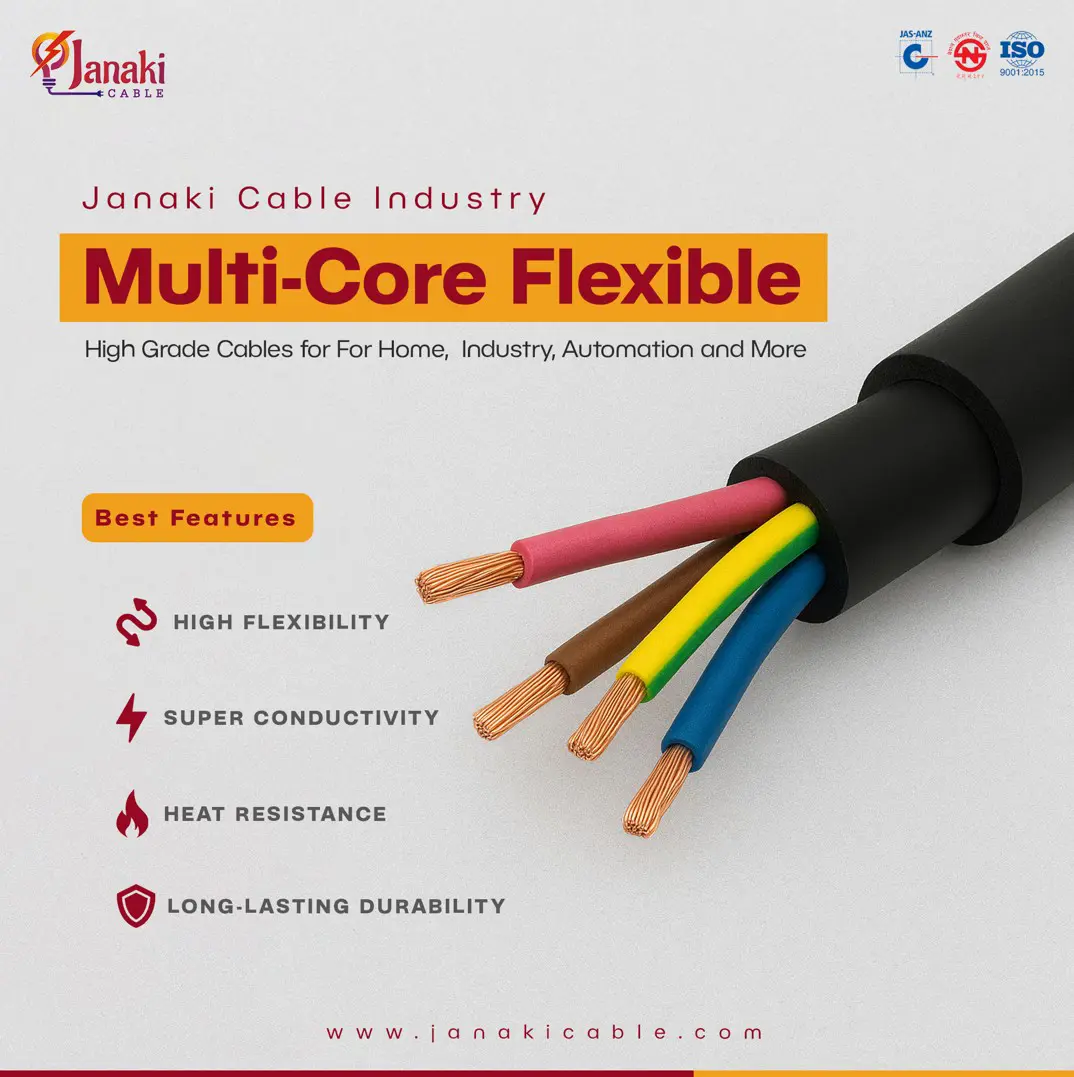

The Importance of Multi-Core Flexible Cables in Nepal

The Importance of Multi-Core Flexible Cables in Nepal’s Growing Industrial Sector

As Nepal’s industrial, commercial, and infrastructure sectors continue to expand, the demand for reliable and efficient electrical wiring solutions has surged. Among the many cable types available in the market, Multi-Core Flexible Cables have become one of the most trusted options for factories, automation systems, construction projects, and advanced machinery.

These cables combine strength, flexibility, and safety, making them ideal for environments where wiring must withstand movement, vibration, and long operational hours. For factories in Nepal, installing industrial control panels and modern electrical setups often relies heavily on such quality wiring solutions.

What Are Multi-Core Flexible Cables?

Multi-core flexible cables consist of multiple insulated copper conductors enclosed within a flexible outer sheath. Unlike rigid cables, these are specifically engineered to bend, twist, and adapt to dynamic environments without damaging the internal wiring.

This makes them perfect for:

Industrial machines

Portable equipment

Robotics and manufacturing lines

In Nepal, where industries increasingly rely on automation and modern equipment, these cables have become a foundational component of safe and efficient electrical systems.

Why Multi-Core Flexible Cables Matter in Nepal

Ideal for Industrial Machinery & Automation

Factories and workshops in Nepal—from metal, textile, food processing, to hydropower-related equipment, require wiring that can handle continuous movement and vibration. Multi-core flexible cables are designed for exactly that, ensuring seamless power and signal transmission.Ensures Safety in Challenging Environments

Nepal’s industrial zones often face dust, moisture, and temperature fluctuations. A well-manufactured multi-core flexible cable provides:

Strong outer insulation

Mechanical protection

Resistance to wear and tear

This significantly reduces the risk of electrical faults or equipment downtime, helping businesses comply with Nepal-specific safety standards.

Supports Modern Electrical Installations

As new factories, data centers, and commercial buildings adopt advanced electrical systems, flexibility becomes crucial. Multi-core cables fit easily into tight spaces, conduits, and moving machines, making installations faster and more efficient.Cost-Effective for Long-Term Use

Though slightly more expensive upfront compared to rigid wires, multi-core flexible cables save money in the long run. Their durability means fewer replacements, fewer breakdowns, and better equipment life. Local providers like Janaki Cable Industry Limited offer high-quality solutions suitable for Nepal’s industrial requirements.

Applications of Multi-Core Flexible Cables in Nepal

These cables are commonly used in:

CNC machines & automation lines

Construction equipment

Packaging machinery

Elevators & lifts

Renewable energy setups, including solar cables

Portable tools

Whether it’s a factory in Birgunj, a manufacturing unit in Hetauda, or a commercial building in Kathmandu, these cables deliver reliable performance across sectors.

Choosing the Right Multi-Core Flexible Cable in Nepal

When selecting cables, it’s important to consider:

Conductor quality (pure copper is best)

Number of cores

Insulation & sheath material

Voltage rating

Flexibility level

Safety standards

Local manufacturers like Janaki Cable Industry provide Nepal-specific cable solutions that meet industrial needs while ensuring long-term durability.

Conclusion

Multi-Core Flexible Cables play a vital role in Nepal’s growing industrial and commercial landscape. Their flexibility, strength, and reliability make them ideal for modern machines, automation systems, and complex electrical setups.

As Nepal continues to advance technologically, choosing high-quality cables ensures safety, efficiency, and long-lasting performance across all industries.

For more information on quality cables, you can explore Janaki Cable’s full range of wiring products in Nepal.